Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

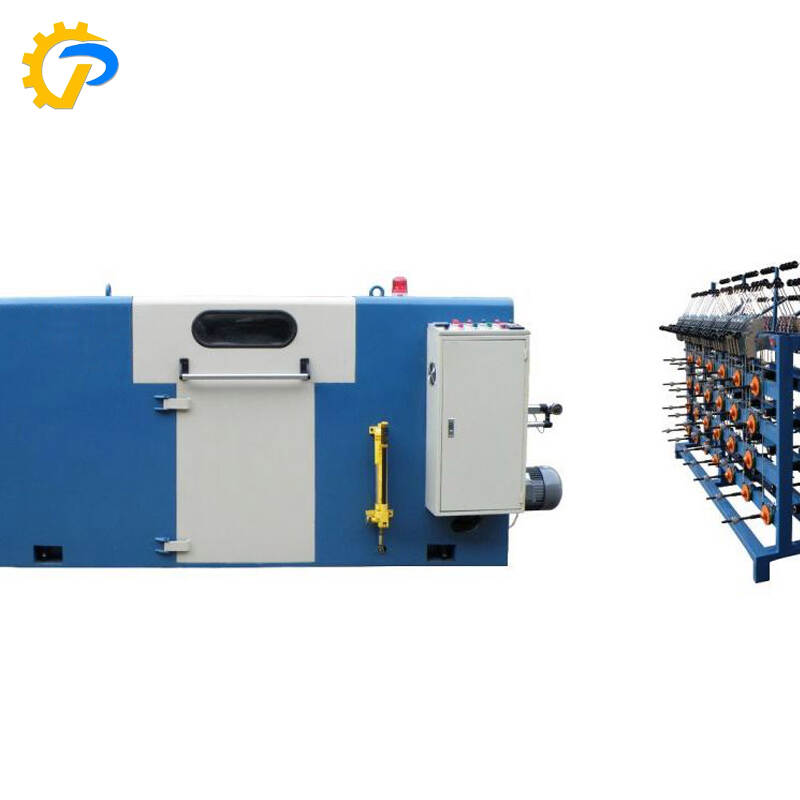

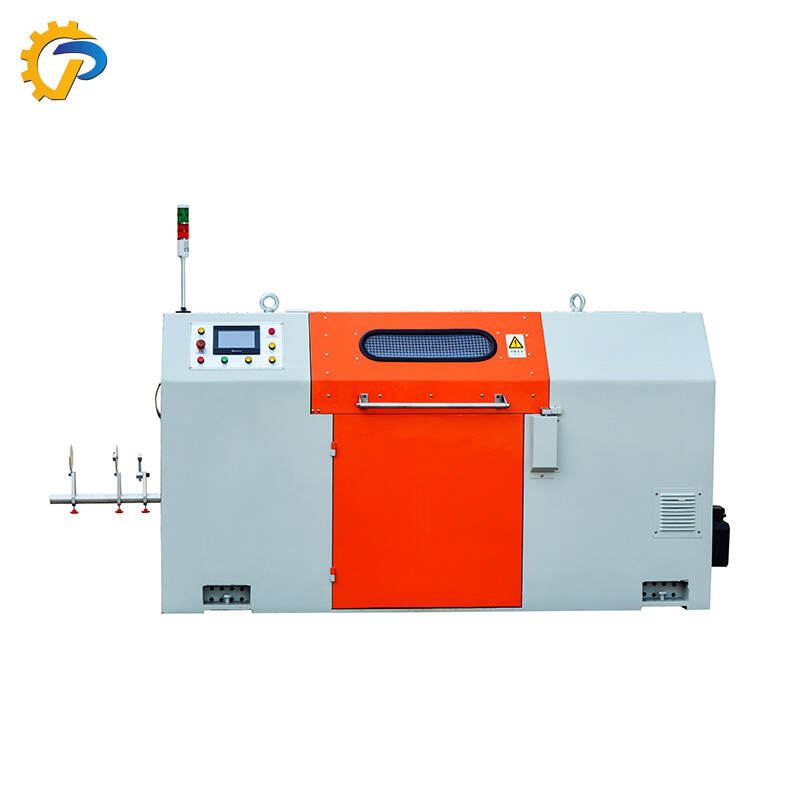

800 bunching machine

The 800 Bunching Machine is designed for efficient cable production, handling finished wire cross-sections from 2.5 mm² to 10 mm² and input wire diameters ranging from 0.23 mm to 1.05 mm. With advanced features like double gear change pitch and a user-friendly control system, this machine ensures high precision and reliability, making it an ideal choice for modern cable manufacturing facilities.

Product Features

Advanced Pitch Change Mechanism:

The double gear change pitch system allows precise control over the bunching process, ensuring consistent and high-quality cable production. This feature is essential for meeting various cable specifications and requirements.

Robust and Safe Box Structure:

The machine features a sliding door structure made of Q235 steel, with safety protection and electromagnetic self-locking devices. The welded and annealed construction eliminates internal stress and ensures long-term durability.

High-Quality Spindle and Bearings:

The spindle is made of 40Cr steel, with the shaft center quenched and tempered to HB250. The main engine bearings are high-quality NSK products from Japan, ensuring smooth operation and reduced wear.

Swing Arm Cradle and Twisted Bow:

The swing arm cradle structure ensures smooth wiring, while the twisted bow is made of spring steel strip, equipped with porcelain eyes and guide wheels for optimal conductor handling.

User-Friendly Control System:

The machine features a human-machine interface (HMI) control system, allowing easy operation and real-time monitoring. The system includes settings for wire twisting parameters, tension control, and fault detection, enhancing production efficiency and cable quality.

Technical Specifications

Product Advantages

Constant Tension Control:

The magnetic powder clutch automatically adjusts tension, ensuring consistent tension from an empty to a full winding shaft. This feature improves cable quality and reduces production defects.

Efficient Wire Reel Mechanism:

The electric hydraulic type wire reel up and down mechanism ensures smooth and precise operation, enhancing production efficiency and reducing downtime.

Data Recording and Sampling:

The machine includes a setting and sampling function for wire twisting parameters, allowing detailed records of production data for quality control and process optimization.

Energy-Saving Design:

The exhaust fan and lighting are controlled by touch switches, which can be turned off when not in use, reducing energy consumption and operating costs.

Clear Fault Detection:

The machine features a pull-down red font display for clear and immediate fault detection, including internal and external wire breakage. This ensures quick troubleshooting and reduced downtime.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost